23++ Bearing lubrication calculation worksheet For Free

Home » Live Worksheets » 23++ Bearing lubrication calculation worksheet For FreeYour Bearing lubrication calculation worksheet images are available. Bearing lubrication calculation worksheet are a topic that is being searched for and liked by netizens today. You can Download the Bearing lubrication calculation worksheet files here. Find and Download all royalty-free photos.

If you’re searching for bearing lubrication calculation worksheet pictures information linked to the bearing lubrication calculation worksheet keyword, you have visit the ideal site. Our site frequently provides you with suggestions for refferencing the maximum quality video and picture content, please kindly hunt and locate more enlightening video content and images that fit your interests.

Bearing Lubrication Calculation Worksheet. Knowing the bearing number or dimensions generalizations can be made and a rough quantity of grease can be determined. Once the required grease volume has been calculated you will need to determine how often to apply that amount of grease. Those listed in this section make up the most commonly identified causes of damage for anti-friction bearings including cylindrical spherical tapered and ball designs. The ability to verify that the selected lubricant is a good choice.

Hydraulics Pneumatics Ppt Download Hydraulic Fluid Surface Tension Hydraulic Systems From pinterest.com

Hydraulics Pneumatics Ppt Download Hydraulic Fluid Surface Tension Hydraulic Systems From pinterest.com

3232010 92810 AM. Lubrication 91 Lubrication amount for the forced lubrication method When a rolling bearing runs at high speed the rolling friction of the bearing itself and the churning of lubricant cause heat generation resulting in substantial temperature rise. Get thousands of teacher-crafted activities that sync up with the school year. 80 of grease lubricated bearings fail to achieve minimum life-cycle levels due. Calculating Bearing Requirements for Oil Lubricants. Re-lubrication Amount of Grease g 0005 Bearing Outside Diameter mm Total Bearing Width mm.

Please use our tool SKF Bearing Select to calculate bearing frequencies of SKF catalogue bearings where no geometry input is required.

N bearing rpm ng speed rating of bearing. The formula is as follows. LubeCoach improves lubrication practices and productivity and reduces maintenance costs in any industrial environment. 3232010 92810 AM. Get thousands of teacher-crafted activities that sync up with the school year. Ad The most comprehensive library of free printable worksheets digital games for kids.

Source: pinterest.com

Source: pinterest.com

A full array of variables to use for estimating bearing regrease frequencies and volumes. Best Regards Michael Meehan CMRP CRL. One way of determining the quantity of grease comes from the bearing suppliers. V A x T V volume in terms of lube-oil replacement rate in cubic inches per hour in³hr A bearing surface area in square inches in² sized differently based on bearing type T film thicknessgenerally 001 inchbut it may vary based on oil type and application Calculating Bearing Requirements for Grease Lubricants. Those listed in this section make up the most commonly identified causes of damage for anti-friction bearings including cylindrical spherical tapered and ball designs.

Lubricated bearing varies with the type and size of bearing. This calculator can be used to calculate bearing frequencies based on manual input of bearing geometry data. The ability to verify that the selected lubricant is a good choice. Re-lubrication Amount of Grease g 0005 Bearing Outside Diameter mm Total Bearing Width mm. Machine Lubrication Calculation Calculate Optimize Grease Lubrication Practices at Your Fingertips.

V A x T V volume in terms of lube-oil replacement rate in cubic inches per hour in³hr A bearing surface area in square inches in² sized differently based on bearing type T film thicknessgenerally 001 inchbut it may vary based on oil type and application Calculating Bearing Requirements for Grease Lubricants. All maintenance is conditional and when you have the opportunity to use technology that tells you the condition take it. Get thousands of teacher-crafted activities that sync up with the school year. Machine Lubrication Calculation Calculate Optimize Grease Lubrication Practices at Your Fingertips. Best Regards Michael Meehan CMRP CRL.

Source: pinterest.com

Source: pinterest.com

Timken Bearing Life Calculations Created Date. Even if the bearings are immedi-ately lubricated the non-lubricated surfaces are still prone to corrosion. Positive removal or dissipation of such generated heat serves greatly to prevent overheating in. Therefore it is advisable to apply a light anti-corrosion coating to these bearing surfaces after lubrication. Ad The most comprehensive library of free printable worksheets digital games for kids.

A full array of variables to use for estimating bearing regrease frequencies and volumes. Get thousands of teacher-crafted activities that sync up with the school year. LubeCoach improves lubrication practices and productivity and reduces maintenance costs in any industrial environment. P b Bearing pressure psi K 1 for single oil hole K 2 for central groove W load lbs l bearing length as defined in. 3232010 92810 AM.

Source: tstar.com

Source: tstar.com

Lubrication 91 Lubrication amount for the forced lubrication method When a rolling bearing runs at high speed the rolling friction of the bearing itself and the churning of lubricant cause heat generation resulting in substantial temperature rise. The following formulas provide a complete lubrication analysis which forms the basis for the bearing design. With a high-speed angular contact ball bearing the d mn value should be 140104 as a guideline. Grease types A lithium-based grease whose base oil is mineral oil is commonly used as a lubricant for rolling bearings as. A full array of variables to use for estimating bearing regrease frequencies and volumes.

Source: gmn.de

Source: gmn.de

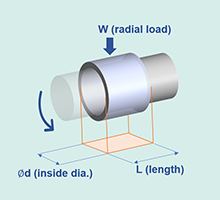

A full array of variables to use for estimating bearing regrease frequencies and volumes. V A x T. P b W K l d Where. Grease types A lithium-based grease whose base oil is mineral oil is commonly used as a lubricant for rolling bearings as. This formula works for all bearings and is widely accepted as the best way to calculate grease quantity.

Source: pinterest.com

Source: pinterest.com

V A x T V volume in terms of lube-oil replacement rate in cubic inches per hour in³hr A bearing surface area in square inches in² sized differently based on bearing type T film thicknessgenerally 001 inchbut it may vary based on oil type and application Calculating Bearing Requirements for Grease Lubricants. V A x T V volume in terms of lube-oil replacement rate in cubic inches per hour in³hr A bearing surface area in square inches in² sized differently based on bearing type T film thicknessgenerally 001 inchbut it may vary based on oil type and application Calculating Bearing Requirements for Grease Lubricants. Please use our tool SKF Bearing Select to calculate bearing frequencies of SKF catalogue bearings where no geometry input is required. Lubricated bearing varies with the type and size of bearing. Lubrication 91 Lubrication amount for the forced lubrication method When a rolling bearing runs at high speed the rolling friction of the bearing itself and the churning of lubricant cause heat generation resulting in substantial temperature rise.

Source: slidetodoc.com

Source: slidetodoc.com

Timken Bearing Life Calculations Created Date. This calculation is more complex. All maintenance is conditional and when you have the opportunity to use technology that tells you the condition take it. Otherwise a specified calculation to determine the amount of grease and the relubrication frequency will be best to help avoid one of the most frequent mistakes made in one of the most common lubrication practices. Calculation of Journal Bearing Dynamic Characteristics 95 NOMENCLATURE B damping coefficient C damping matrix c radial clearance F load vector h oil film thickness distribution K stiffness matrix L bearing length N number of mesh nodes P oil film hydrodynamic pressure R journal radius W applied load z crankshaft axial direction oil film domain δδ small.

Source: pinterest.com

Source: pinterest.com

Ad The most comprehensive library of free printable worksheets digital games for kids. Once the required grease volume has been calculated you will need to determine how often to apply that amount of grease. Ad The most comprehensive library of free printable worksheets digital games for kids. This formula works for all bearings and is widely accepted as the best way to calculate grease quantity. The formula is as follows.

V A x T V volume in terms of lube-oil replacement rate in cubic inches per hour in³hr A bearing surface area in square inches in² sized differently based on bearing type T film thicknessgenerally 001 inchbut it may vary based on oil type and application Calculating Bearing Requirements for Grease Lubricants. 2015 The Timken Company TIMKEN BEARING DAMAGE ANALSIS WITH LUBRICATION REFERENCE GUIDE 7 Types of Bearing Damage Many different operating conditions can cause bearing damage. Once the required grease volume has been calculated you will need to determine how often to apply that amount of grease. The formula is as follows. One way of determining the quantity of grease comes from the bearing suppliers.

Source: za.pinterest.com

Source: za.pinterest.com

The innovative and easy to use LubeCoach E includes. 2015 The Timken Company TIMKEN BEARING DAMAGE ANALSIS WITH LUBRICATION REFERENCE GUIDE 7 Types of Bearing Damage Many different operating conditions can cause bearing damage. P b Bearing pressure psi K 1 for single oil hole K 2 for central groove W load lbs l bearing length as defined in. Otherwise a specified calculation to determine the amount of grease and the relubrication frequency will be best to help avoid one of the most frequent mistakes made in one of the most common lubrication practices. Timken Bearing Life Calculations Keywords.

Source: pinterest.com

Source: pinterest.com

Get thousands of teacher-crafted activities that sync up with the school year. Lubrication 91 Lubrication amount for the forced lubrication method When a rolling bearing runs at high speed the rolling friction of the bearing itself and the churning of lubricant cause heat generation resulting in substantial temperature rise. 2015 The Timken Company TIMKEN BEARING DAMAGE ANALSIS WITH LUBRICATION REFERENCE GUIDE 7 Types of Bearing Damage Many different operating conditions can cause bearing damage. Machine Lubrication Calculation Calculate Optimize Grease Lubrication Practices at Your Fingertips. Calculating Bearing Requirements for Oil Lubricants.

Source: pinterest.com

Source: pinterest.com

80 of grease lubricated bearings fail to achieve minimum life-cycle levels due. 2015 The Timken Company TIMKEN BEARING DAMAGE ANALSIS WITH LUBRICATION REFERENCE GUIDE 7 Types of Bearing Damage Many different operating conditions can cause bearing damage. The formula is as follows. Get thousands of teacher-crafted activities that sync up with the school year. Lubricant prior to storage.

Machine Lubrication Calculation Calculate Optimize Grease Lubrication Practices at Your Fingertips. Positive removal or dissipation of such generated heat serves greatly to prevent overheating in. Even if the bearings are immedi-ately lubricated the non-lubricated surfaces are still prone to corrosion. Ad The most comprehensive library of free printable worksheets digital games for kids. Lubrication 91 Lubrication amount for the forced lubrication method When a rolling bearing runs at high speed the rolling friction of the bearing itself and the churning of lubricant cause heat generation resulting in substantial temperature rise.

Source: pinterest.com

Source: pinterest.com

2015 The Timken Company TIMKEN BEARING DAMAGE ANALSIS WITH LUBRICATION REFERENCE GUIDE 7 Types of Bearing Damage Many different operating conditions can cause bearing damage. Timken Bearing Life Calculations Keywords. For applications exceeding this range consult NTN Engineering. The following formulas provide a complete lubrication analysis which forms the basis for the bearing design. This formula works for all bearings and is widely accepted as the best way to calculate grease quantity.

Source: pinterest.com

Source: pinterest.com

Grease types A lithium-based grease whose base oil is mineral oil is commonly used as a lubricant for rolling bearings as. A full array of variables to use for estimating bearing regrease frequencies and volumes. This timeframe is known as the regreasing frequency. V A x T V volume in terms of lube-oil replacement rate in cubic inches per hour in³hr A bearing surface area in square inches in² sized differently based on bearing type T film thicknessgenerally 001 inchbut it may vary based on oil type and application Calculating Bearing Requirements for Grease Lubricants. This article was previously published in the Machinery Lubrication 2018 Conference Proceedings.

Source: pinterest.com

Source: pinterest.com

Calculating Bearing Requirements for Oil Lubricants. Those listed in this section make up the most commonly identified causes of damage for anti-friction bearings including cylindrical spherical tapered and ball designs. Otherwise a specified calculation to determine the amount of grease and the relubrication frequency will be best to help avoid one of the most frequent mistakes made in one of the most common lubrication practices. This article was previously published in the Machinery Lubrication 2018 Conference Proceedings. Grease types A lithium-based grease whose base oil is mineral oil is commonly used as a lubricant for rolling bearings as.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title bearing lubrication calculation worksheet by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.